VANCOUVER, BC / ACCESSWIRE / MARCH

12th, 2014 / GLOBAL COBALT CORP. (TSXV:GCO)

("Global Cobalt" and/or the

"Company") (TSXV:GCO)

reports the most recent results from the Winter 2013 diamond

drill program at the Karakul Cobalt Project ("Karakul") that

continue to duplicate and support a metal

zonation geological model that demonstrates Karakul Cobalt Deposit

includes high grade cobalt, high grade copper and higher grading

tungsten and bismuth zones than previous work had

indicated.

The 2013 results are leading the exploration team to

consider the deeper, bulk tonnage underground potential of Karakul

and are contributing to a greater understanding of the zonation of

metals within mineralised zones. As a result of greater confidence

in other metals in the deposit, cobalt equivalent ("CoEq") grades

are being reported for the first time at Karakul.

Global Cobalt's team has initiated critical path

items such as updated environmental, social and metallurgical

studies required for mine planning under Russian subsoil

regulations. Global Cobalt has short listed several consultants to

complete updates to previously initiated environmental and social

studies and hope to announce new contracts in the near future.

Planning for additional metallurgical work, including a 750kg bulk

sample is underway as part of the 2014 Work Program that will also

focus on infill and deep drilling at the Western Zone and more

definition drilling along the Eastern Zone where higher grade

cobalt zones have been intersected.

"Each release of assay results

continues to confirm the validity of the historical drill and

technical data but more importantly, we are gaining an

understanding of the unique high grade sections for each metal

group within the Karakul Cobalt Project which is key as we initiate

on mine planning activities," said

Erin Chutter, CEO of Global Cobalt.

Paul Sarjeant, V.

P. Exploration commented, "We have received most of the drill results

from the lab and are currently processing the data. We will be

releasing the results from the final drill holes over the next few

weeks. At that point we will begin working to complete geological

modeling and from that the resource model will follow. Based on

results to date we are excited to advance development at

Karakul."

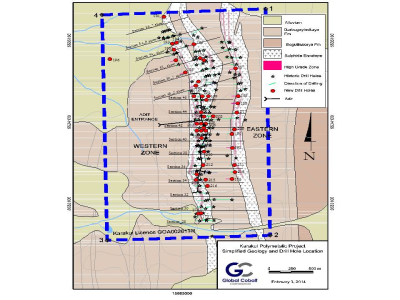

These new results

below, along with qualitative narrative are organized

geographically and their locations are illustrated on the

accompanying map.

Karakul Western Zone - NW Extension

Drill holes 193

and 194 where drilled on section 54-4 skewed to test for the

extension of mineralisation 100m south from section 54-8 skewed

where intersections in historic drill holes KK028 (11.8m @ 0.749%

Co, 0.414% Cu, 0.231% Bi and 0.031% WO3),

KK078 (10.4m @ 0.171% Co, 0.023% Cu, 0.03% Bi and 0.026%

WO3), KK079 (15.9m @ 0.127% Co, 1.179%

Cu, 0.059% Bi and 0.276% WO3) and KK120

(23.3m @ 0.120% Co, 0.133% Cu, 0.016% Bi and 0.199%

WO3) outlined a thick zone of

polymetallic mineralisation. Drill holes 193 and 194 were also

drilled in an attempt to explain relatively weak mineralisation in

KK036 (5.0m @ 0.003%Co, 0.030% Cu and 0.08%

WO3) on Section 54-4 skewed.

-------------------------------------------------------------------

|Hole # |From |To |Length*|Co |Cu |Bi |WO3 |Ag |CoEq |

| |(m) |(m) |(m) |(%) |(%) |(%) |(%) |(g/t)|(%)**|

|-----------------------------------------------------------------|

|193 |45.30|51.90|6.60 |0.155|0.347|0.097|0.011|5.624|0.334|

|-----------------------------------------------------------------|

|194 |62.10|63.20|1.10 |0.028|0.251|0.022|0.000|7.900|0.121|

|-----------------------------------------------------------------|

| |77.70|83.80|6.10 |0.147|0.255|0.156|0.077|3.995|0.425|

|-----------------------------------------------------------------|

|including|78.80|81.70|2.90 |0.236|0.416|0.272|0.132|6.676|0.711|

|-----------------------------------------------------------------|

| |103.1|103.8|0.70 |0.006|1.102|0.001|0.000|12.00|0.297|

-------------------------------------------------------------------

-The key intercepts in drill

holes 193 (45.3m to 51.9m) and 194 (77.7m to 83.8m) correlate well

on section and demonstrate the mineralised zones persists south to

Section 54-4 skewed.

^-Intercepts in drill holes

193 and 194 show little correlation with historic drill hole KK036

(on section) and confirms structural complexity of the

area.

-Further, closer spaced

drilling is required for greater understanding.

Drill hole 181 was

drilled 400m to the north of section 54-4 skewed and did not

intersect any significant results.

Karakul Western Zone - South Adit Area

Drill hole 213 (Section

35) was drilled to confirm and extend mineralised zone in Soviet

era historic drill hole KK022 (8.6m @ 0.102% Co, 0.579% Cu and

0.167% Bi).

-------------------------------------------------------------------------

|Hole # |From |To |Length* (m)|Co |Cu |Bi |WO3 |Ag |CoEq |

| |(m) |(m) | |(%) |(%) |(%) |(%) |(g/t)|(%)**|

|-----------------------------------------------------------------------|

|213 |90.50 |91.70 |1.20 |0.013|0.275|0.086|0.106|7.600|0.288|

|-----------------------------------------------------------------------|

| |108.40|117.70|12.60 |0.020|0.274|0.005|0.054|1.062|0.159|

|-----------------------------------------------------------------------|

|including|114.40|117.70|3.30 |0.019|0.403|0.007|0.090|1.609|0.235|

-------------------------------------------------------------------------

-Mineralisation at 108.40m to

117.70m appears to spatially correlate well with the primary

historical intercept in KK022.

-Results provide up dip

confirmation of the mineralised zone - approximate 100m separation

on section.

-Deepest intercept in historic

drill hole KK022 shows good grades and demonstrate mineralised

zones remain open at depth.

Drill holes 214 and 215

(Section 34-5) were drilled to test extension of mineralised zones

on this section that had not been previously drilled from surface.

Both drill holes were targeted to trace mineralisation encountered

in horizontal underground historic drill holes KK115 (no

significant results) and KK116 (8.6m @ 0.039% Co, 0.299% Cu and

0.013% Bi and 3.0m @ 0.10% Co and 0.01% Cu).

----------------------------------------------------------------

|Hole|From |To |Length*|Co |Cu |Bi |WO3 |Ag |CoEq |

|# |(m) |(m) |(m) |(%) |(%) |(%) |(%) |(g/t)|(%)**|

|--------------------------------------------------------------|

|214 |54.40 |55.50 |1.10 |0.005|0.218|0.004|0.017|3.400|0.088|

|--------------------------------------------------------------|

| |88.40 |91.40 |3.00 |0.015|0.114|0.032|0.000|0.240|0.066|

|--------------------------------------------------------------|

| |94.10 |94.90 |0.80 |0.011|0.239|0.029|0.012|9.000|0.123|

|--------------------------------------------------------------|

| |123.10|123.80|0.70 |0.006|0.032|0.005|0.061|0.800|0.094|

|--------------------------------------------------------------|

|215 |195.90|198.20|2.30 |0.013|0.737|0.030|0.040|9.439|0.281|

----------------------------------------------------------------

-The key mineralised zones are

represented in drill hole 214 by intercepts at 88.40m to 91.40m and

94.1m to 94.9m and they correlate well with the mineralised zone

defined in KK116.

-Mineralisation intercepted in

drill hole 215 at 195.9m to 198.2m appears to extend the

mineralised zone to depth approximately 80m down dip from historic

drill hole KK116.

-Overall, drill hole results

indicate that mineralised zones are present as predicted, though

grade variability is evident with lower cobalt grades but stronger

copper and bismuth grades as compared to historic

results.

-Mineralisation remains open

to depth with deepest intercept in drill hole 215 exhibiting

strongest overall grades.

Drill hole 216 (Section

33-5) was targeted to confirm and extend mineralisation in historic

drill hole KK136 (6.7m @ 0.102% Co, 0.484% Cu and 0.024% Bi).

---------------------------------------------------------------------

|Hole # |From |To |Length*|Co |Cu |Bi |WO3 |Ag |CoEq |

| |(m) |(m) |(m) |(%) |(%) |(%) |(%) |(g/t)|(%)**|

|-------------------------------------------------------------------|

|216 |103.10|104.30|1.20 |0.015|0.287|0.000|0.039|2.500|0.138|

|-------------------------------------------------------------------|

| |237.10|242.00|4.90 |0.059|0.373|0.007|0.009|2.845|0.170|

|-------------------------------------------------------------------|

|including|240.10|242.00|1.90 |0.102|0.564|0.008|0.008|4.200|0.262|

---------------------------------------------------------------------

-Drill hole 216 successfully

intercepted mineralisation from 237.1m to 242.0m and correlates

well with the location of the main mineralised zone identified in

KK136. The deepest intercept in drill hole 216 is approximately

220m below surface.

-Mineralisation remains open

to depth.

-Results appear to confirm

interpretation of mineralised zones.

Sample Preparation and Analysis

All drill core was

logged, photographed and cut in half with a diamond saw. Half of

the core was bagged, numbered and sent to Stewart Geochemical and

Assay (a subsidiary of ALS Global) of Moscow, Russia. All samples

were first analysed using ICP-MA technique that reports cobalt,

copper, bismuth and tungsten in parts per million (10,000 ppm =

1%). Any samples reporting greater than 2,000 ppm cobalt or bismuth

and any samples reporting greater 10,000 ppm copper were then

assayed by ICP-ORE methodology. Samples reporting greater than

2,000 ppm tungsten were then assayed using the ME-MS61 method and

reported as WO3. The results were verified by the application of

industry standard Quality Control and Quality Assurance (QA-QC)

procedures including laboratory internal duplicate sampling.

* Note: Lengths quoted

represent core lengths and do not necessarily represent the true

thickness of mineralised intervals. Samples were analysed by

Stewart Geochemical and Assay

** Note:

Cobalt equivalent (CoEq%) values are given for illustration to

express the aggregate content of cobalt, copper, bismuth, tungsten

and silver as a percent cobalt. This is calculated assuming 100%

metal recovery using metal prices of US$13.60/lb cobalt US$3.26/lb

copper, US$9.89/lb bismuth, $US16.73/lb tungsten and US$20 per troy

ounce silver. The cobalt equivalent calculation is as follows; CoEq

= Co grade + (Cu% x 0.24) + (Bi% x 0.73) + (WO3% x 1.23) + (Ag g/t

x 0.002)

Global Cobalt

Corporation:

Global Cobalt Corporation is a

Canada-based strategic metals company focused on the development of

a new mining region in the Republic of Altai. Global Cobalt

will build upon the success of the Altai

Projects while aggressively expanding and exploring existing

properties to meet the demand for cobalt and other strategic

metals.

For Further

Information:

Mr. Mitchell Smith, Corporate

Development

Suite 1510-1050 West Pender

Street

Vancouver, BC V6E 3T4

Tel: +1 (604) 688-4219

Fax: +1 (604) 688-4215

Email: info@globalcobaltcorp.com

www.GlobalCobaltCorp.com

TSXV:GCO; FRA:3P0;

CUSIP:37890F

Cautionary

Statement on Forward-Looking Information: The statements made in

this News Release may contain certain forward-looking statements.

Actual events or results may differ from the Company's

expectations. Certain risk factors may also affect the actual

results achieved by the Company.

This news

release shall not constitute an offer to sell or the solicitation

of any offer to buy, nor shall there be any sale of these

securities in any jurisdiction in which such offer, solicitation or

sale would be unlawful. The shares offered will not be and have not

been registered under the United States Securities Act of 1933, as

amended (the "U.S. Securities Act") and may not be offered or sold

in the United States absent registration or an applicable exemption

from the registration requirements of the U.S. Securities Act and

applicable state securities laws.

Neither TSX

Venture Exchange nor its Regulation Services Provider (as that term

is defined in the policies of the TSX Venture Exchange) accepts

responsibility for the adequacy or accuracy of this release.

Figure 1. Karakul Polymetallic Project

- Simplified Geology and Drill Hole Location

Click Image To View Full Size